DETECT CRITICAL FAILURES EARLY

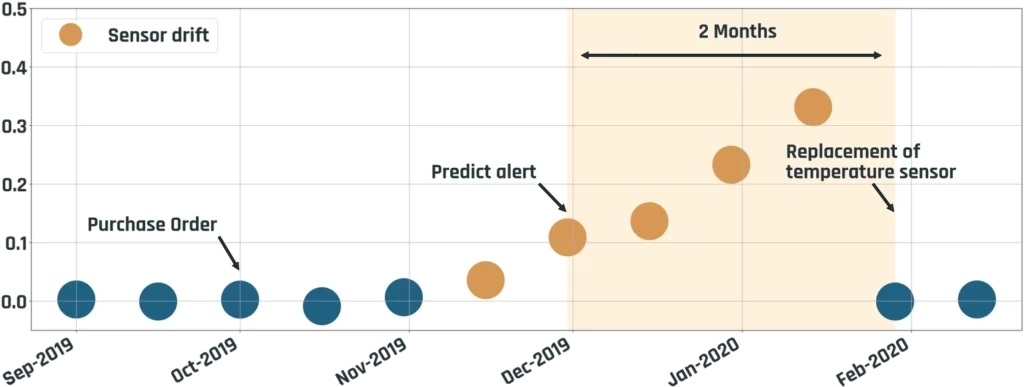

Predict began working with a global mining company in 2019 to reduce maintenance costs and failures across a critical Nickel processing workshop. After a thorough engineering study, Predict designed indicators to closely monitor signifi cant changes across the process including the regulation of the hot gas generator.

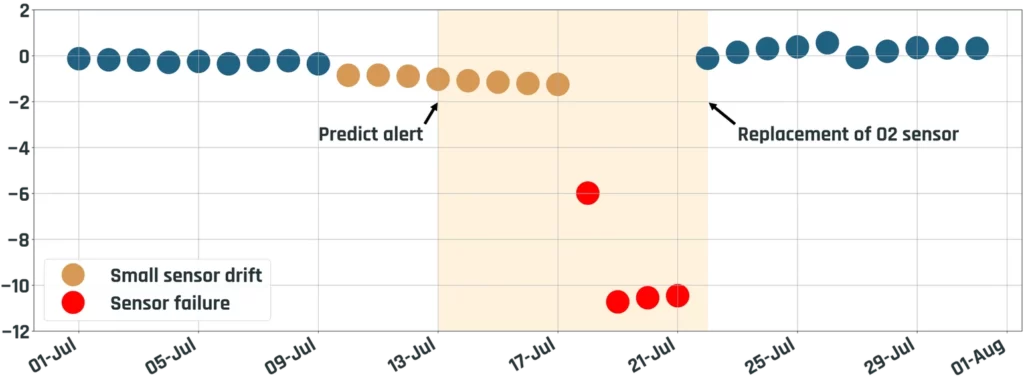

This indicator generated an alert that was provided to the reliability team in November 2019 through Predict’s cloud-based platform KASEM® that the regulation system was not performing correctly. The team watched the indicator closely as they investigated the issue, ultimately fi nding a drifting temperature sensor to be the root cause.

Replacement of this sensor was able to be scheduled for an upcoming shutdown, avoiding any impact to production. Upon analysis, Predict’s alert of this sensor drift was provided 1.5 months before any local low alarms and 3.5 months before the high alarm with an interlock.